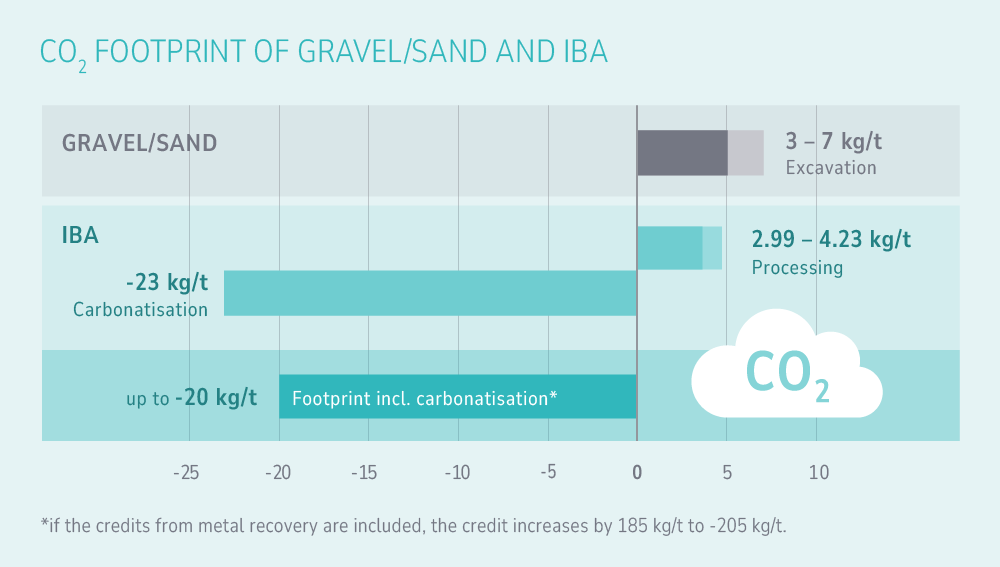

CO₂ ist permanently bound

A study by the Institute for Circular Resource Engineering and Management (CREM) at the Technical University of Hamburg shows that during storage, IBA reacts with CO₂ from the atmosphere – a natural process known as carbonation. The data shows that up to 23 kg of CO₂ are permanently bound per tonne of bottom ash. IBA aggregates are therefore not only a high-quality substitute construction material, but also make a measurable contribution to reducing emissions.

Additional climate benefits through metal recovery

The recovery of ferrous and non-ferrous metals during IBA processing further improves the carbon footprint. The metals separated from the ash replace primary metals, the production of which is extremely energy-intensive. This results in significant CO₂ credits. According to the new expert report, the total CO₂ footprint reches around -205 kg CO₂e per tonne of ash treated.

Alternative to natural materials – also regarding transport

Compared to mineral raw materials, incinerator bottom ash causes lower emissions during production. While sand and gravel cause 3 to 7 kg CO₂e per tonne, the values for processed IBA range between 2.99 and 4.23 kg CO₂e, depending on the electricity mix – and that is before carbonation is taken into account.

In total, this results in a CO₂ footprint of up to -20 kg CO₂e per tonne, even when the energy required for processing is taken into account. These emission credits enable climate-neutral transport over longer distances without the slag losing its potential as a climate-friendly alternative to primary building materials.

The industry sees considerable potential here: “The use of HMV slag as a building material closes material cycles, reduces dependence on primary raw materials and actively contributes to climate protection,” emphasises Dieter Kersting, CEO of the German federation of ash processing companies (IGAM), which commissioned the expert opinion. Therefore, the potential should finally be exploited more fully, especially in the context of sustainable public procurement.

Learn more about the climate-related potential of IBA in the CREM study conducted by the Technical University of Hamburg.