Around 6 million tonnes of raw bottom ash are produced in Germany every year as part of the thermal treatment of muncipal solid waste. The residues serve as a valuable pool of resources. According to the Association of Thermal Waste Treatment Plants (ITAD), around 500,000 tonnes of metals are recovered from them. However, the industry still sees great potential in the fine fraction with grain sizes of up to 3 mm. This is now to be tapped with the EMSARZEM research project.en.

The fine fraction of incinerator bottom ash (IBA) accounts for approximately 25 % of annual residues, amounting to up to 1.5 million tonnes. Estimates put its copper content at 0.3 to 0.4 % and its gold content at around 1 to 2 ppm. EMSARZEM aims to develop a process that extracts the heavy metals as far as possible through crushing, grinding, screening, magnetic and eddy current separation, and washing. The prerequisite for the economic implementation of this approach is the high-quality utilisation of the minerals that are subsequently available in finely ground form. Suitable application opportunities might be found in the cement industry.

In order to use the ground mineral components of ash as a raw material in cement production, they would have to be largely freed of metals such as lead, chromium, cobalt, nickel, vanadium and zinc, as well as chlorine and sulphur. If this were achieved, it would provide the cement industry with an additional source of raw material for clinker production – with positive effects for the environment. On the one hand, the use of the calcium oxide available in the slag would reduce CO₂ emissions and energy consumption, while on the other hand, the higher raw material productivity would protect natural resources.

EMSARZEM stands for the German abbreviation for a research collaboration on the utilisation of the fine fraction of incinerator bottom ash in cement production.

The project, which is scientifically supported by the German Cement Association (VDZ) and the University of Duisburg-Essen, is coordinated by GKS-Gemeinschaftskraftwerk Schweinfurt GmbH. The companies C.C. Umwelt GmbH and REMEX GmbH were brought in as experts for the IBA processing. DK Recycling und Roheisen GmbH is assisting with the recovery of magnetic components from the processed ash. The cement industry is represented by Dyckerhoff GmbH, while Steinert GmbH and Loesche GmbH are contributing their experience in the field of processing plants.

The EMSARZEM project consists of seven work packages. Step six, the large-scale trial with around 15 tonnes of ground fine IBA was completed in 2024. Based on the results, all project participants will carry out an economic and ecological assessment. It will then become clear whether bottom ash from waste incineration will have a future in cement.

„This process can theoretically separate 8,000 tonnes of copper concentrate per year from an originally worthless mass – worthless because it is extremely finely distributed in the waste. It would contain approximately 2,800 tonnes of copper, 20 tonnes of silver and 100 kg of gold.“

Prof. Rüdiger Deike, Lehrstuhl Metallurgie und Umformtechnik an der Universität Duisburg-Essen

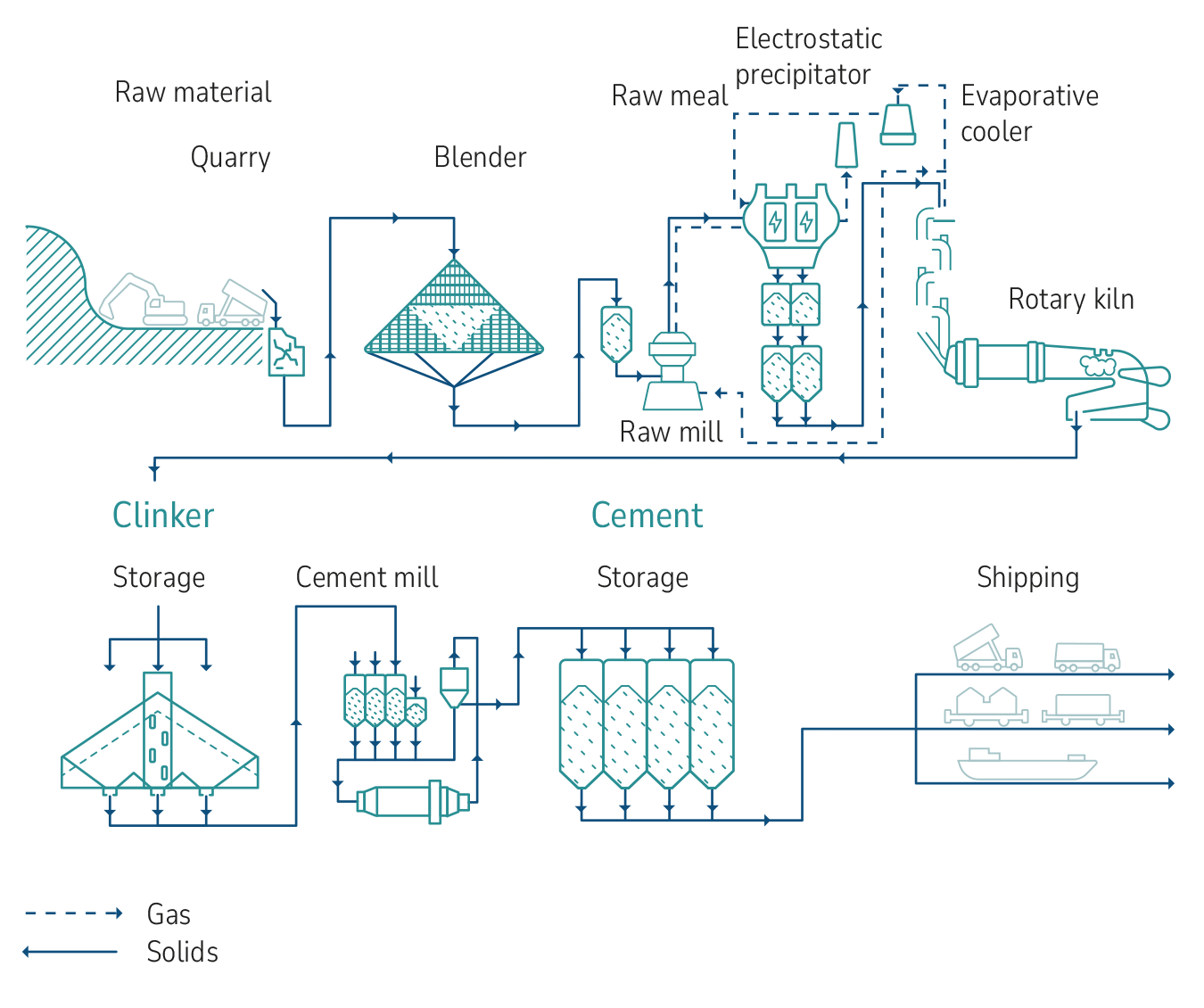

Schematic representation of cement production

Source: Zement-Taschenbuch, 51. Ausgabe, VDZ

Cement clinker is an interim product in cement production. Raw meal is heated to 1,450°C in a rotary kiln. This produces calcium compounds known as clinker phases, which give cement its characteristic hydraulic properties. The clinker is then ground into cement in cement mills with the addition of calcium sulphate.

State funding of €1.5 million for EMSARZEM

As part of the funding measure Resource-Efficient Circular Economy – Construction and Mineral Material Cycles (ReMin), the EMSARZEM project is being funded with around €1.5 million under the reference number 033R265. With this initiative, the Federal Ministry of Education and Research aims to increase resource efficiency in the construction industry and promote the use of secondary mineral raw materials from construction waste, slag, ash and mining residues.