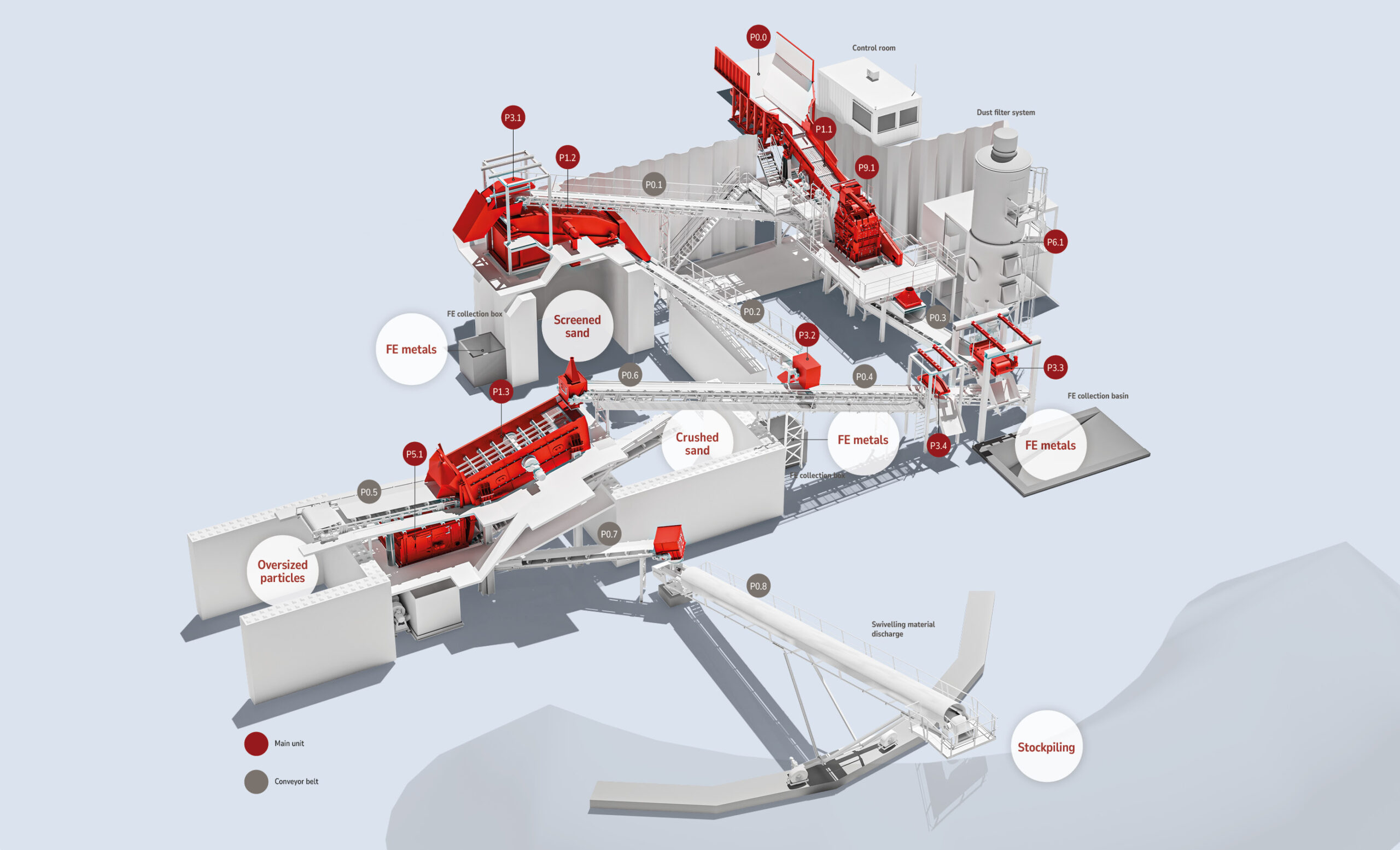

The project involves a complete overhaul of the existing processing plant. Key components such as impact crusher, screening systems and wind sifter will be installed to ensure precise separation of the material fractions. The plant will be supplemented by a powerful dust filter system, modern magnetic separators and automated lubrication and weighing systems – for reliable and environmentally friendly operation.

There is a particular focus on digitalisation: a new control room with modern visualisation software, a camera system and data recording enables central control of all processes. The result is a forward-looking plant that combines state-of-the-art recycling technology with a sustainable material cycle and transforms construction waste into valuable raw materials.

The plant in detail – explore the technology

Flexible grain size separation thanks to up to three variable screening mats

Separation of light impurities using air separation technology to purify the minerals

Flexibly adjustable gap size enables crushing to individual grain sizes

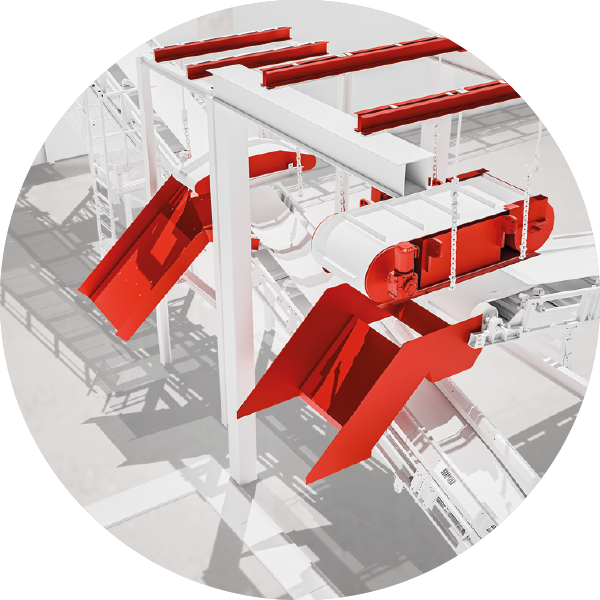

Overband magnet separates the ferrous metals exposed after crushing

The path of the material

Thanks to state-of-the-art technology, digital control and high processing capacity, Cologne‘s plant is a pioneer in recycling. Further information on our recycling technologies can be found on remex-processing.com