Revised concrete standard includes R-concrete

Until now, R-concrete has been manufactured and used in accordance with the relevant guideline issued by the German Committee for Reinforced Concrete (DAfStB). With the revised DIN 1045-2 published in August 2023, this recognised state of the art has now been codified in a German standard. The standard applies to in-situ concrete structures, precast concrete structures and precast elements for buildings and civil engineering structures. It does not apply to concrete products, which continue to be governed by the relevant standards and guidelines.

Concrete design crucial

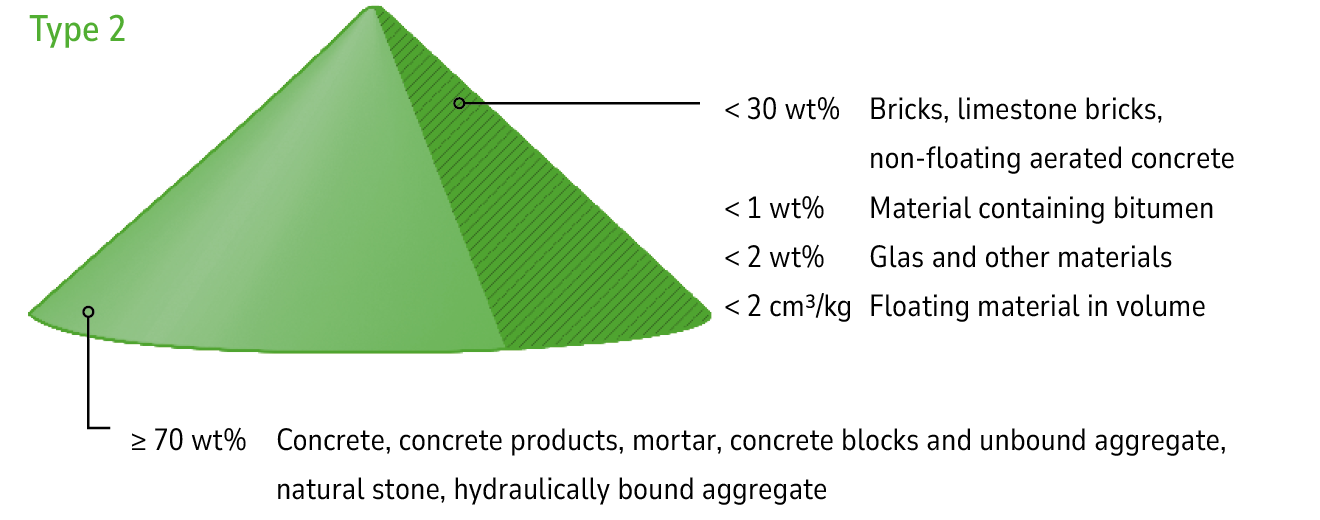

The design and construction of concrete or reinforced concrete structures is carried out in the form of a structural analysis. This determines the building material requirements, including those for concrete. The concrete compressive strength required for the planned structure and the exposure/moisture classes, which take into account environmental influences such as frost or chemical attack, are specified. These requirements affect the concrete mix designs.

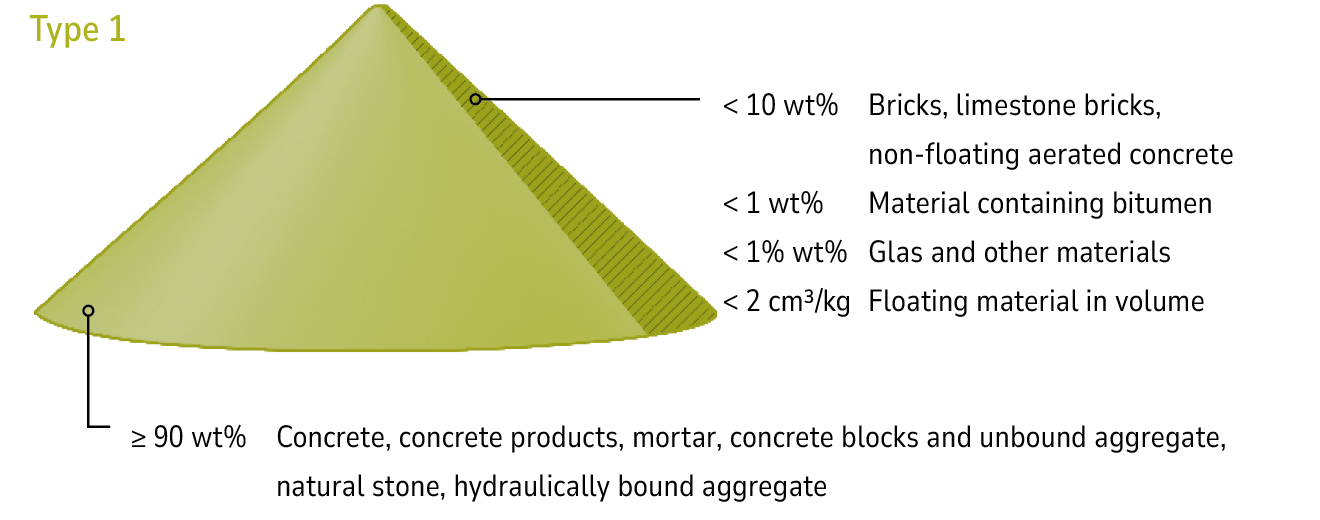

Distinction of recycled aggregate types

DIN 1045-2 allows the use of two types of recycled aggregates in concrete production. Type 1 consists of at least 90 % by weight (wt%) of concrete or natural stone. For type 2, this minimum proportion is 70 wt%. Type 1 aggregates have a wider range of applications. For example, type 1 material may also be used as fine (< 2 mm) recycled aggregate under defined conditions; this is not permitted for type 2 materials.

Permitteld recyling ratios

Concrete is made from three main components: cement, water and aggregate. The natural aggregate can be replaced by recycled concrete material in proportion. The maximum possible recycled content is 45 per cent by volume (vol%) of coarse (> 2 mm) type 1 aggregates and 35 vol% of coarse type 2 aggregates. Depending on the required concrete compressive strengths and environmental influences, the permissible volume proportions are lower.

Prerequisite for suitable recycled aggregate qualities

The composition of construction waste is fundamental to the quality of recycled building materials. Concrete, bricks, plasterboard and bituminous road rubble must be separated during professional demolition work on construction sites. Only then can they be optimally processed in recycling plants and only then can recycled materials meet the high quality requirements for use as concrete aggregates. Another challenge relates to the expected composition of construction site waste in the future. While concrete, bricks and limestone bricks were the main building materials used in the post-war years, composite materials became increasingly popular in the following decades. The building stock from this period is now reaching the end of its lifespan and is increasingly being renovated and demolished. In the foreseeable future, the proportion of concrete and natural stone in demolition material will therefore be lower than before.

The German market

Of the approximately 77 million tonnes of recycled aggregates produced in German plants in 2020, around 15 million tonnes were used in concrete and asphalt production. The majority of recycled aggregates, 56.4 million tonnes, are used in road construction and earthworks. The German construction industry’s total demand amounts to 585 million tonnes per year. Recycled construction materials can cover around 13 % of this amount. In order to meet the future demand of the concrete industry, further mineral material flows must therefore be tapped.

Definition of R-concretes according to DIN 1045-2

Securing sufficient quantities: a look abroad

In addition to natural and recycled aggregates, German concrete standards regulate the use of granulated blast furnace slag, blast furnace slag and melting chamber granulate. Other industrially produced alternative materials, such as bottom ash from waste incineration which has been used in concrete production in the Netherlands for many years, are not yet covered by German standards. In view of the concrete industry’s ambitious sustainability goals and the associated high demand for materials, it seems time to give serious consideration to solutions such as these as well.

The technical and regulatory requirements for resource-efficient concrete production are in place. Now, the focus is on the quality and sufficient availability of suitable recycled resources – and being open to new, alternative material flows. A look at neighbouring countries such as the Netherlands shows that there are practical solutions that will also contribute to climate transition in the construction sector.